![]()

Product Features

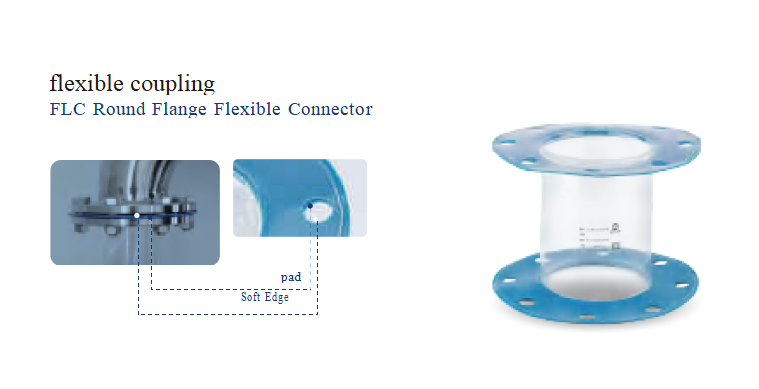

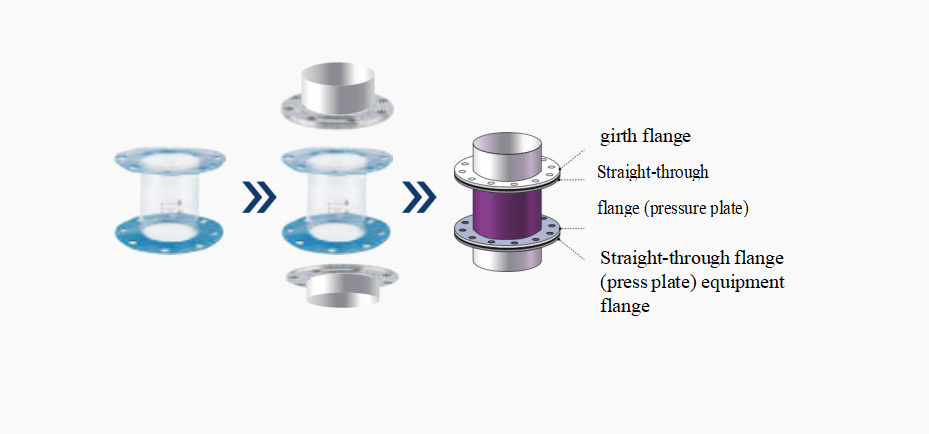

Compatible with standard round interfaces with built-in flanges at both ends

It is tightly connected by two flange pressure plates pressed in the middle

Suitable for high sealing reliability requirementsand equipment points that don't need to be disassembled frequently

![]()

Installation Instructions

Fit the flange pressure plate on the flexible hose, then tighten the bolts at both ends in sequence to complete the installation.

Material Parameters

| material | PU10 | PUHT | PUAS |

| material | polyurethane | Heat-resistant polyurethane | Antistatic polyurethane |

| Applicable conditions | Most common materials | high temperature | Flammable and explosive powder |

| pigment | transparent | transparent | transparent |

| thickness (mm) | 1.0 | 1.0 | 1.0 |

| abrasion (mg) | 39 . 0 | 35 . 0 | 39 . 0 |

| sheet resistance (Q) | 12 >10 | 12 >10 | <10' |

| temperature resistance (C) | -20 ~ 110 | -20 ~ 150 | -20 ~ 110 |

| ventilate | airtight | airtight | airtight |

| Tensile strength (MPa) | 40 | 40 | 15 |

| Section elongation (%) | 600% | 600% | 600% |

| For food contact | can | can | can |

| production engineering | hot melt | hot melt | hot melt |

| | | |

|

| material | PURF | PUFL | TE02 | TE02AS |

| material | Fiber-reinforced polyurethane | Polyurethane with spiral steel wire | 100% polytetrafluoroethylene | 100% polytetrafluoroethylene |

| Applicable conditions | Positive or negative pressure conditions | Swing wideand travel coordination agency | Corrosive acids, alkalis, solvents, high temperature | Corrosive acids, alkalis, solvents, high temperature |

| pigment | white | White translucent | white | black |

| thickness (mm) | 0.8 | 0.6 | 0 . 2 | 0.2 |

| abrasion (mg) | 39 . 0 | 35 . 0 | | |

| sheet resistance (Ω) | 12 >10 | 12 >10 | 12 >10 | |

| temperature resistance (C) | -20 ~ 110 | -20 ~ 110 | 40 ~300 | 40 ~300 |

| ventilate | airtight | airtight | airtight | airtight |

| Tensile strength (MPa) | 300 | 40 | | |

| Section elongation (%) | 600% | 600% | 10% | 10% |

| For food contact | can | can | can | can |

| production engineering | hot melt | hot melt | hot melt | hot melt |