![]()

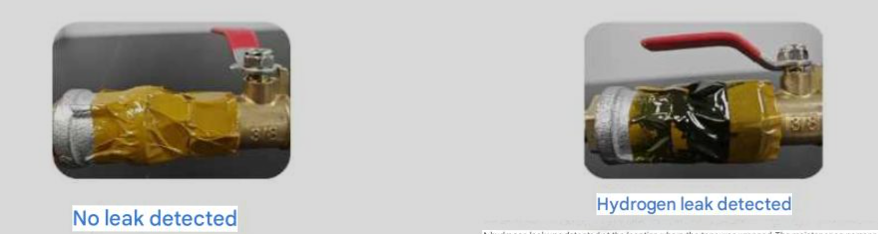

When the adhesive surface is exposed to H2, the tape can change color from amber to black within 10 seconds (depending on flow rate, volume, temperature, time, and percentage of hydrogen).

It has extremely high sensitivity to hydrogen and can detect leaks of hydrogen containing 1% H2.

It can slowly recover its original color in a hydrogen-free environment and is reusable;

Easy to operate, the usage method is the same as traditional silicone pressure-sensitive adhesive;

It has strong weather resistance and can be used in most indoor or outdoor environments.

Test method:

1. Connect pipes of different diameters to create an intentional hydrogen leak.

2. Inject 100% hydrogen gas into the pipeline at a flow rate of 100 mL/min, and visually inspect its condition after approximately 1 minute

![]()

Key Features and Applications:

- Leak Detection: Hydrogen Sensitivity: Hydrogen detection tapes are chemically sensitive and change color when exposed to hydrogen gas. This visual change indicates the presence of a hydrogen leak, allowing for immediate action to prevent potential hazards. Non-Intrusive Monitoring: The tape can be easily applied to surfaces or areas where hydrogen leakage might occur, providing a simple and cost-effective method for ongoing monitoring without the need for complex equipment.

- Color Change Mechanism: Visual Indicators: When the tape comes into contact with hydrogen, it undergoes a color transformation. This color change acts as an immediate visual cue, indicating the concentration of hydrogen and whether there is a leak. Quick Response: The tape provides quick feedback, which is crucial in safety-critical environments such as hydrogen storage facilities, laboratories, fuel cells, and pipelines.

- Safety in Various Environments: Hydrogen Storage & Transport: Used to monitor hydrogen gas in storage tanks, pipelines, and transportation systems to detect any potential leakage early on. Fuel Cells: Commonly used in fuel cell systems to ensure hydrogen is contained properly and to alert personnel if any leakage is detected. Industrial & Laboratory Use: In chemical plants, research labs, and manufacturing facilities where hydrogen is used, the tape helps monitor and secure equipment and infrastructure. Automotive Industry: In hydrogen-powered vehicles, the detection tape can be applied to check for leaks in hydrogen tanks or piping.

- Ease of Use: Simple Application: The tape is easy to apply to different surfaces, such as pipes, valves, joints, or tanks. It doesn't require specialized equipment or complicated procedures. Affordable and Efficient: As a low-cost solution, hydrogen detection tape is an effective alternative to more expensive and complex gas detection systems, making it accessible for smaller operations or as a supplementary monitoring tool.

- Durability and Reliability: Long-Lasting: The tape is designed to be durable under normal operating conditions, remaining functional for extended periods without significant degradation. Robust Against Environmental Conditions: It is resistant to a variety of industrial environments, ensuring reliability even in harsh conditions.

Summary:

Hydrogen Detection Tape is a practical, cost-effective solution for monitoring hydrogen gas leaks in various industrial, automotive, and laboratory settings. By using a simple color-change mechanism, the tape provides immediate visual confirmation of hydrogen presence, contributing to safety in environments where hydrogen is handled. Its ease of use, reliability, and low cost make it a valuable tool in hydrogen leak detection and prevention.