Custom Processing of Neodymium Iron Boron Permanent Magnets

NdFeB (Neodymium Iron Boron) permanent magnets are high-performance rare-earth magnets made from a combination of neodymium (Nd), iron (Fe), and boron (B). They are known for their exceptionally high magnetic energy product and long-lasting magnetic properties. These magnets are used in various industries, including electronics, automotive, wind energy, and more. Our company provides custom processing services for NdFeB permanent magnets, ensuring that each magnet meets specific performance and dimensional requirements for your applications.

Key Features:

1. High Magnetic Performance:

• NdFeB permanent magnets have the highest magnetic energy product of any permanent magnet, offering strong and stable magnetic fields. This makes them ideal for high-power applications where maximum magnetic strength is required.

2. High Temperature Stability:

• Specially processed NdFeB magnets can operate at higher temperatures, with some high-temperature grades able to function at up to 200°C or higher, making them suitable for industrial and automotive applications in harsh environments.

3. Corrosion Resistance:

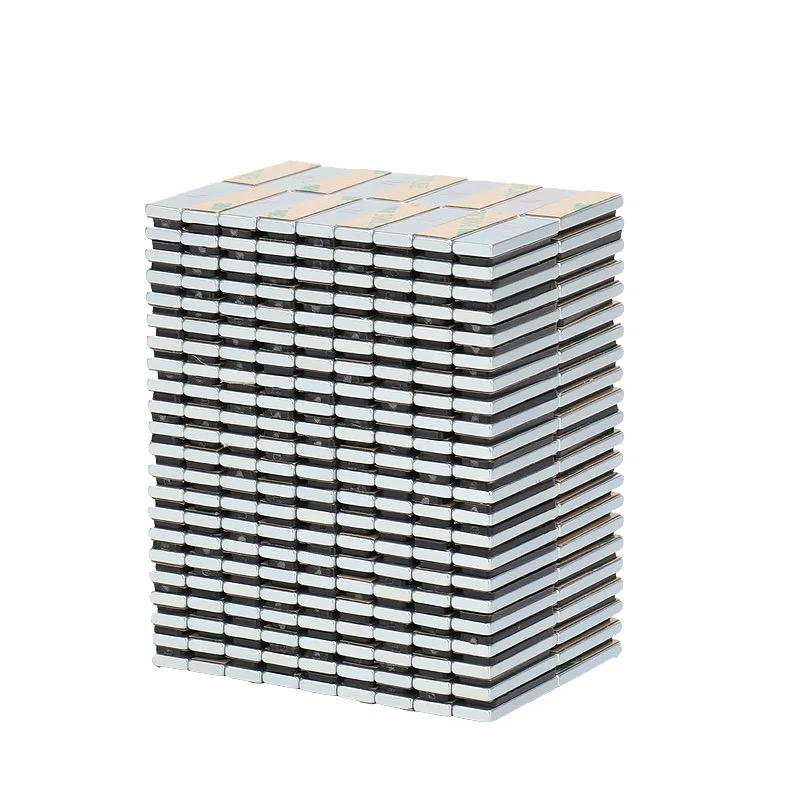

• NdFeB magnets are prone to corrosion, but we offer surface treatments such as nickel-plating, zinc-plating, gold-plating, or epoxy coating to enhance their resistance to environmental factors, ensuring a longer service life.

4. Custom Manufacturing:

• We offer tailored solutions based on customer specifications, producing magnets in various shapes, sizes, and magnetic strength. Whether you need rings, discs, blocks, or other custom shapes, we can provide precision manufacturing for any requirement.

5. Precision Processing:

• Using advanced machinery and technologies, we ensure precise dimensions, shapes, and magnetic properties. Each magnet is carefully processed and undergoes strict quality control to ensure it meets international standards.

6. Environmental & Safe:

• All NdFeB magnets comply with international environmental standards, ensuring they are non-toxic and safe to handle. We ensure that our products do not harm the environment or human health during use.

Applications:

• Electric Vehicles (EVs): Used in electric motor systems to enhance power and efficiency, essential for EV propulsion.

• Wind Power Generation: NdFeB magnets are critical components in wind turbines, improving energy conversion efficiency.

• Robotics: Widely used in industrial robots and automation systems, offering precise control and motion.

• Consumer Electronics: Used in devices such as headphones, speakers, hard drives, and motors.

• Medical Devices: Essential in magnetic resonance imaging (MRI), magnetic therapy equipment, and other advanced medical instruments.

• Industrial Motors and Drives: Commonly found in high-performance electric motors and mechanical drive systems.

Product Specifications & Customization Options:

Parameter

Specification

Material Composition

Neodymium (Nd), Iron (Fe), Boron (B)

Shapes

Ring, Disc, Block, Custom Shapes

Magnetic Grade

N35-N52 (Customizable)

Size Range

From a few millimeters to several hundred millimeters

Maximum Operating Temperature

Custom grades available, up to 200°C+

Surface Treatment

Nickel Plating, Zinc Plating, Gold Plating, Coatings

Magnetic Properties

Customized based on energy product (BHmax), coercivity, etc.

Customization Requests

Magnetic field direction, dimensional tolerances, and other parameters can be customized

Advantages:

1. Superior Magnetic Strength: Provides strong magnetic fields to meet the requirements of high-power and precision applications.

2. Flexible Customization: Custom shapes, sizes, magnetic strength, and operating temperature tailored to specific needs.

3. Reliable & Durable: Strict quality control ensures stable, long-lasting performance of each magnet.

4. Wide Application Range: Ideal for use in industries such as electric vehicles, renewable energy, automation, electronics, and medical devices.

Summary:

Our custom NdFeB permanent magnets are high-performance rare-earth magnets that provide exceptional magnetic strength and stability. They are used in a variety of applications such as electric vehicles, wind energy, robotics, medical devices, and consumer electronics. By offering flexible customization options and precision manufacturing, we deliver solutions that meet the specific needs of our customers, ensuring high-quality products that align with industry standards and customer expectations.