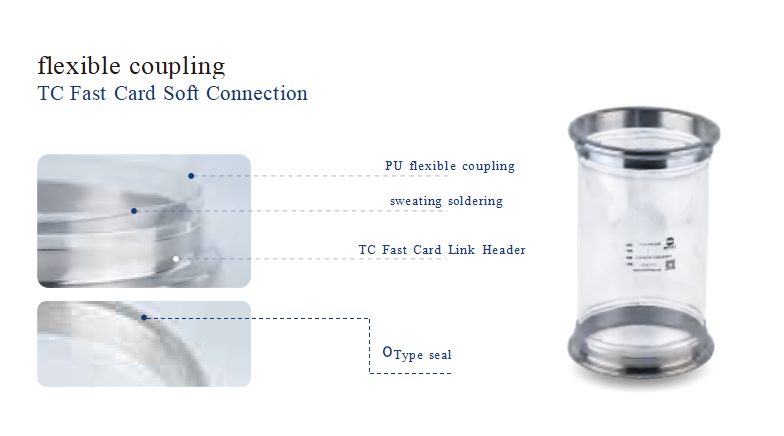

Both ends are equipped with standard stainless steel sanitary-grade quick-connect couplings and standard sanitary-grade quick-connect clamps. Integrated sealing pad eliminates the need for gaskets, saving time and effort Prevent gasket fall and contamination 30S can be easily disassembled and assembled without tools

Both ends are equipped with standard stainless steel sanitary-grade quick-connect couplings and standard sanitary-grade quick-connect clamps.

Integrated sealing pad eliminates the need for gaskets, saving time and effort

Prevent gasket fall and contamination

30S can be easily disassembled and assembled without tools

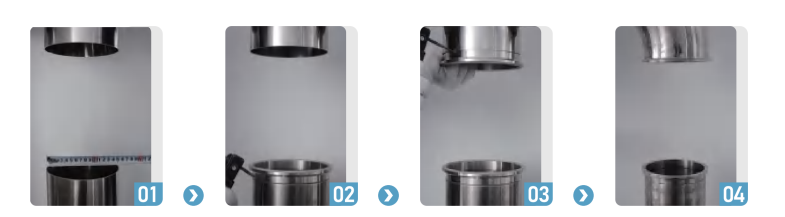

Installation Instructions

Step 1:

Welding TC Fast Connectors (skip this step if the site equipment has already been welded)

Select the appropriate TC quick-connect fitting based on the outer diameter of the on-site equipment or pipeline, and complete the welding of both ends in sequence.

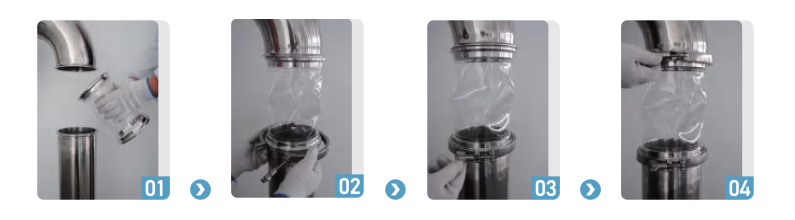

Step 2:

Install TC quick-release clamps on both ends and tighten the bolts to complete the installation.

| TC D152 / C167 TC D152 / C167 i iTC Fast Card Soft Connection Connector Outer Diameter and Card Holder Outer Diameter | CL300 304 / PU10 CL300 304 / PU10 Length Connector Material Soft Connector Material |

| order number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Joint outer diameter D | 76 | 89 | 102 | 104 | 108 | 114 | 127 | 133 | 140 |

| Clamp outer diameter c | 91 | 106 | 119 | 119 | 119 | 130 | 145 | 145 | 155 |

| order number | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Joint outer diameter D | 152 | 154 | 159 | 168 | 180 | 204 | 219 | 254 | 273 |

| Clamping chuck outer diameter c | 168 | 183 | 183 | 183 | 200 | 217 | 233 | 268 | 286 |

| order number | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| Joint outer diameter D | 305 | 325 | 356 | 377 | 406 | 425 | 457 | 476 | 508 |

| Clamping chuck outer diameter c | 319 | 350 | 380 | 400 | 430 | 450 | 480 | 500 | 530 |

length cL:

100 /150/ 200 /250/ 300/ 350/ 400/ 450/ 500/ 550 /600/ 650/ 700/ 750/ 800/ 850/ 900/ 950/ 1000

Other sizes can be customized as needed, with a minimum of 100

Material

Materials Polyurethane Polyurethane Heat-resistant polyurethane Anti-static polyurethane

| Applicable conditions | Most common materials | Weigh and Re-weigh | high temperature | Flammable and explosive powder | |||

| pigment | transparent | transparent | transparent | transparent | |||

| thickness (mm) | 0 . 5 | ||||||

| abrasion (mg) | 39 . 0 | 39 . 0 | 35 . 0 | 39 . 0 | |||

| sheet resistance (Ω) | 12 >10 | 12 >10 | 12 >10 | ||||

| temperature resistance (C) | -20 ~ l10 | -20 ~ l10 | -20 ~ l50 | -20 ~ l10 | |||

| ventilate | airtight | airtight | airtight | airtight | |||

| Tensile strength (MPa) | 40 | 40 | 15 | ||||

| Section elongation (%) | 600% | 300% | 600% | 600% | |||

| For food contact | can | can | can | can | |||

| production engineering | hot melt | hot melt | hot melt | hot melt | |||

| material | Fiber-reinforced polyurethane | Polyurethane with spiral steel wire | 100% polytetrafluoroethylene | 100% polytetrafluoroethylene | |||

| Applicable conditions | Positive or negative pressure conditions | Swing wideand travel coordination agency | Corrosive acids, alkalis, solvents, high temperature | Corrosive acids, alkalis, solvents, high temperature | |||

| pigment | white | White translucent | white | black | |||

| thickness (mm) | 0.2 | 0 . 2 | |||||

| abrasion (mg) | 39 . 0 | 35 . 0 | |||||

| sheet resistance (Ω) | 12 >10 | 12 >10 | 12 >10 | ||||

| temperature resistance (C) | -20 ~ 110 | -20 ~ l10 | 40 ~300 | -40 ~300 | |||

| ventilate | airtight | airtight | airtight | airtight | |||

| Tensile strength (MPa) | 300 | 40 | |||||

| Section elongation (%) | 600% | 600% | 10% | 10% | |||

| For food contact | can | can | can | can | |||

| production engineering | hot melt | hot melt | hot melt | hot melt | |||