Clamp-Style Flexible Tubing: The Secret to Boosting Production Line Efficiency by $50\%$

Clamp-style and snap-fit flexible tubing systems, such as the TC Quick-Clip or jingzheng fitting, can increase production line efficiency by up to 50% by eliminating the inefficiencies of traditional hose clamps and rigid piping

High Transparency Flexible Couplings: Real-Time Material Flow Visualization

TC Quick-Clip high-transparency flexible couplings are transforming modern production lines by enabling a "Visual Factory" environment. These connectors replace traditional opaque rubber sleeves to provide immediate insights into your material handling process.

The End of the Wrench: How Modern Process Pipe Connectors Eliminate Leakage and Maintenance Headaches

Tired of fighting loose clamps, uneven seals, and constant retightening? We break down why traditional pipe clamping methods are obsolete and how engineered connectors deliver guaranteed seal integrity and drastically lower maintenance costs.

Beyond Dust Control: Achieving 100% Leak-Proof Powder Transfer with Industrial High-Sealing Connectors

In sensitive processing environments, anything less than absolute containment is unacceptable. Discover the engineering principles and strategic deployment of high-sealing connectors that guarantee zero leakage for critical powder transfer applications.

The 60-Second Challenge: Quick Connect Hoses for Powder Systems Slash Downtime and Boost OEE

In continuous powder processing, every minute of downtime costs thousands. Learn how implementing specialized Quick Connect Hoses can reduce your system changeover and maintenance time from hours to under 60 seconds, dramatically improving your Overall Equipment Effectiveness (OEE).

✨ High Transparency Flexible Couplings: The Power of Real-Time Material Flow Visualization

In continuous production, what you can't see, you can't control. High transparency flexible couplings are revolutionizing process monitoring, turning connection points from blind spots into critical inspection windows for real-time flow and quality assurance.

Beyond Dust Control: Achieving 100% Leak-Proof Powder Transfer with Industrial High-Sealing Connectors

In sensitive processing environments, anything less than absolute containment is unacceptable. Discover the engineering principles and strategic deployment of high-sesealing connectors that guarantee zero leakage for critical powder transfer applications.

The High-Oscillation Revolution: Customized Flexible Interfaces for Screening Machines Eliminate Downtime and Maximize Throughput

Struggling with seal failures and high maintenance in extreme vibration environments? Discover how our custom-engineered flexible connectors provide the essential isolation, integrity, and longevity your high-frequency screens demand.

Ultra-Durable PU Flexible Connectors: Achieving Zero Leakage & Maximizing Uptime in Powder Systems

Discover how Polyurethane (PU) flexible connectors solve the toughest challenges in industrial powder conveying. Known for high abrasion resistance and ultra-flexibility, PU connectors are the industry standard for achieving reliable, zero-leakage performance in equipment like vibrating screens, mixers, and sifters. Learn the essential selection criteria and why food-grade PU is critical for pharmaceutical and food processing.

🔥 Highly Abrasion-Resistant, Ultra-Flexible! How Polyurethane Flexible Connectors Achieve “Zero Leakage” in Powder Conveying Systems

In demanding industrial powder conveying environments, leakage (Dust Leakage) is the primary threat to production efficiency, safety, and environmental compliance. Traditional flexible connectors often fail rapidly under the dual challenges of high abrasion and frequent vibration. The Polyurethane (PU) Powder Flexible Connector has emerged as the revolutionary solution to this problem, successfully achieving the "zero-leakage" objective in powder handling systems due to its unique material science advantages.

💎 Comprehensive Analysis of Polyurethane Powder Flexible Connectors: Performance, Applications, and Selection Guide

In modern industrial powder conveying systems, the performance of flexible connectors directly determines the system’s sealing integrity, durability, and maintenance costs. Traditional rubber or canvas connectors often prove inadequate when facing high abrasion and frequent vibration. The Polyurethane (PU) Powder Flexible Connector has emerged as the ideal solution to the common industry pain points of "leakage" and "frequent replacement," thanks to its unique material properties.

🚀 Stop Dust Leaks and Downtime: The Ultimate Guide to Polyurethane Flexible Connectors (PU Flexible Connector) in Industry

Why Your Plant Must Upgrade Its Flexible Connection System (H2) In bulk material handling industries like food, pharmaceuticals, and chemicals, Flexible Connectors or Sleeves are crucial components linking vibrating screens, hoppers, and filling heads. However, traditional hose clamp connections often lead to dust leaks, cross-contamination, and costly maintenance downtime. The patented Polyurethane (PU) Flexible Connector has emerged as the industry standard solution. This guide deeply analyzes the core advantages of PU sleeves, key selection criteria, and how upgrading this single component can drastically improve your plant's safety, efficiency, and compliance.

Polyurethane TPU Expansion Joints: Features, Benefits, and Applications

In pipeline systems, flexibility and durability are crucial for long-term, reliable performance. Polyurethane TPU expansion joints are widely used to connect pipes and absorb movements caused by thermal expansion, vibrations, and misalignments. Made from thermoplastic polyurethane (TPU), these expansion joints offer superior wear resistance, elasticity, and excellent sealing properties. This article will explore the key features, advantages, and applications of Polyurethane TPU expansion joints.

Improving Pipeline System Performance: 6 Benefits of Polyurethane Flexible Joints

In industrial pipeline systems, the choice of connectors and joints directly impacts system performance, longevity, and operating costs. As industrial demands evolve, polyurethane flexible joints are increasingly becoming the ideal solution for pipeline systems due to their outstanding performance. Not only do they enhance system efficiency, but they also extend the lifespan of equipment. In this blog, we will discuss the six key benefits of polyurethane flexible joints and how they contribute to improving pipeline system performance.

Why Polyurethane Flexible Joints Are the Ideal Choice for Industrial Piping Systems

In the world of industrial piping systems, selecting the right type of connectors and joints is critical for performance, longevity, and safety. Among the various options available, polyurethane flexible joints stand out as a preferred choice for many industries. But why are they considered ideal? In this blog post, we’ll explore the benefits of polyurethane flexible joints and why they are becoming the go-to solution for industrial piping applications.

How Quick-Clamp Connectors Can Boost Your OEE by 30%

In modern manufacturing, efficiency (OEE) and safety are critical measures of success. Yet, many companies still rely on outdated, low-integrity clamps and bolted flanges for critical process pipe connections. These traditional methods are a constant source of leakage, costly maintenance, and safety risks. Traditional Pain Points: Uneven sealing force, vulnerability to thermal cycling and vibration, and the need for frequent manual retightening (wasting man-hours). The Solution: Adopt Engineered Quick-Connect Solutions for immediate operational gains.

Lifespan and Maximization Strategies for High-Quality Polyurethane (PU) Flexible Joints

How Long Will Your PU Joint Last? 5 Key Factors for Lifespan Prediction For the powder and bulk solids handling industry, flexible connectors are critical determinants of system uptime and Overall Equipment Effectiveness (OEE). When specified correctly, a high-quality Polyurethane (PU) flexible joint significantly outlasts standard rubber or PVC alternatives, with expected continuous operating ranges from 6 months to over 2 years. However, lifespan prediction is not a fixed number. Understanding these five core factors is key to accurately assessing and maximizing your PU joint lifespan.

Price and sales of hydrogen leak tape factory from China

Hydrogen detection tape (reversible & irreversible) from Chinese factories offers cost-effective solutions for leak monitoring. Quick color change for safety.

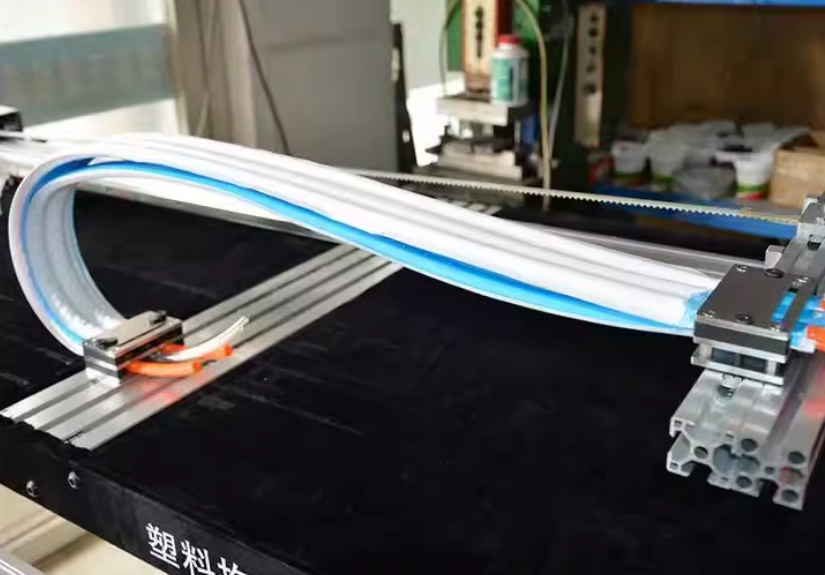

Flexible Dust-Free Drag Chain

A Flexible Dust-Free Drag Chain is a specialized cable management system used in industrial automation, machinery, and production lines. Its primary function is to guide and protect cables, hoses, and other connections, preventing them from friction, stretching, or damage during mechanical movement. Additionally, it is designed to prevent the accumulation of dust and debris, making it ideal for environments that require high hygiene standards, such as clean rooms, semiconductor manufacturing, and pharmaceutical production.

Choosing the Best Polyurethane (PU) Flexible Connections for Food Factory Pipelines

Food and beverage manufacturing demands connectors that prioritize hygiene, safety, and compliance above all else. When selecting Polyurethane (PU) flexible connections for pipelines in a food factory, the choice isn't just about durability—it's about ensuring product purity and meeting stringent regulatory standards. The best type of PU flexible joint for this environment is the FDA-Compliant, Platinum-Cured Ether-Based Polyurethane Connector, often paired with a Hygienic Quick-Clamp System.